Iibholiti zentloko ye-Stainless Flange

Inkcazo

iibholiti zentloko ye-flange zisetyenziselwa ukudibanisa iinxalenye ezimbini okanye ngaphezulu ndawonye ukwenza indibano nokuba ayinakwenziwa njengenxalenye enye okanye ukuvumela ukugcinwa kunye nokulungiswa kweentloko ze-disassembly.flange zisetyenziselwa ukulungiswa kunye nomsebenzi wokwakha.banentloko yeflange kwaye beza nemicu yomatshini yokuphatha okuqinileyo kunye nokurhabaxa.Ziza kuluhlu olubanzi lweebholiti zentloko ezahlukeneyo zeflange zosetyenziso ngokwesiko ngokuxhomekeke kwiimfuno zayo.Ezi iibholiti zentloko ye-flange ziza kwi-anti-corrosion stainless steel, i-alloy steel kunye ne-carbon steel materials eqinisekisa ukuba isakhiwo asibi buthathaka ngenxa yomhlwa.Ngokuxhomekeke kubude bebholithi, inokuza kunye ne-threading standard okanye i-threading epheleleyo.

IZICELO

iibholiti zentloko ye-flange zingasetyenziselwa izicelo ezininzi ezahlukeneyo ezibandakanya ukuqinisa iinkuni, intsimbi, kunye nezinye izinto zokwakha kwiiprojekthi ezinjengee-docks, iibhulorho, izakhiwo zendlela, kunye nezakhiwo.

Izikrufu zentsimbi ezimnyama ziyakwazi ukumelana nomhlwa kancinci kwindawo ezomileyo.Izikrufu zensimbi ezifakwe kwi-zinc zixhathisa ukubola kwiindawo ezimanzi.Izikrufu zentsimbi ezigqunywe nge-ultra-corrosion-resistant-coated zixhathisa iikhemikhali kwaye zimelana neeyure eziyi-1,000 zetyuwa yokutshiza.khetha ezi bholiti ukuba awuyazi imisonto nge-intshi nganye.Imisonto emihle kunye neyongezelelweyo-eyongezelelweyo isondelelene ngokusondeleyo ukukhusela ukukhulula kwi-vibration;Okukhona umsonto ucocekile, kokukhona uxhathisa.

Intloko yebholithi yenzelwe ukulingana ne-ratchet okanye i-spanner torque wrenches ekuvumela ukuba uqinise ibholt kwi-specifications yakho echanekileyo. Iibholithi zentloko ze-flange ziqhele ukusetyenziselwa ukwenza i-bolted joint, apho i-threaded shaft ifanelana ngqo nomngxuma ocofayo ohambelanayo okanye i-nut.Iibholithi zeBanga lesi-2 zikholisa ukusetyenziswa ekwakhiweni kokudibanisa izinto zomthi.Iibholiti zeBakala 4.8 zisetyenziswa kwiinjini ezincinci.Iibholithi zeBakala 8.8 10.9 okanye 12.9 zinika amandla okuqina aphezulu.Enye inzuzo ye-bolts fasteners ine-welds okanye i-rivets kukuba ivumela ukuchithwa lula ukulungiswa nokugcinwa.

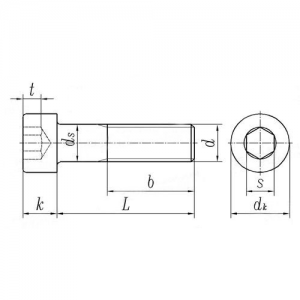

| Icacisiwe | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | M20 | ||

| P | Ububanzi | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | |

| 125<L≤200 | - | - | 28 | 32 | 36 | 40 | 44 | 52 | ||

| L = 200 | - | - | - | - | - | - | 57 | 65 | ||

| c | Min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |

| da | Umzekelo | Max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 |

| B Umzekelo | Max | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |

| dc | Max | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |

| ds | Max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | ||

| du | Max | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |

| dw | Min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

| e | Min | 8.56 | 10.8 | 14.08 | 16.32 | 19.68 | 22.58 | 25.94 | 32.66 | |

| f | Max | 1.4 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | |

| k | Max | 5.4 | 6.6 | 8.1 | 9.2 | 10.4 | 12.4 | 14.1 | 17.7 | |

| k1 | Min | 2 | 2.5 | 3.2 | 3.6 | 4.6 | 5.5 | 6.2 | 7.9 | |

| r1 | Min | 0.25 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | |

| r2 | Max | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | |

| r3 | Min | 0.1 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | |

| r4 | Isalathiso | 3 | 3.4 | 4.3 | 4.3 | 6.4 | 6.4 | 6.4 | 8.5 | |

| s | Max | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| Min | 7.64 | 9.64 | 12.57 | 14.57 | 17.57 | 20.16 | 23.16 | 29.16 | ||

| t | Max | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.45 | 0.5 | 0.65 | |

| Min | 0.05 | 0.05 | 0.1 | 0.15 | 0.15 | 0.2 | 0.25 | 0.3 | ||

| Iziqwenga eziliwaka zobunzima bentsimbi≈kg | - | - | - | - | - | - | - | - | ||

| Ubude bomsonto | - | - | - | - | - | - | - | - | ||